When selecting a pleated filter cartridge for industrial liquid or gas filtration, most people focus on media type, micron rating, and length. However, one critical but often overlooked component is the end cap configuration—a key factor that determines compatibility, sealing efficiency, and overall performance.

At Unimarshal Technologies Pvt. Ltd., we manufacture and export a wide range of pleated filter cartridges with various end cap types, designed to fit standard housings used across pharmaceutical, food & beverage, chemical, and water treatment industries.

Table of Contents

Toggle🔍 What Are End Caps in Pleated Filter Cartridges?

End caps are the molded or welded terminations found at one or both ends of a pleated filter cartridge. They serve two main purposes:

- Provide a secure seal to prevent bypass of unfiltered liquid

- Ensure proper installation and fitment into filter housings

End caps are usually made from polypropylene, stainless steel, or other polymeric materials based on application requirements.

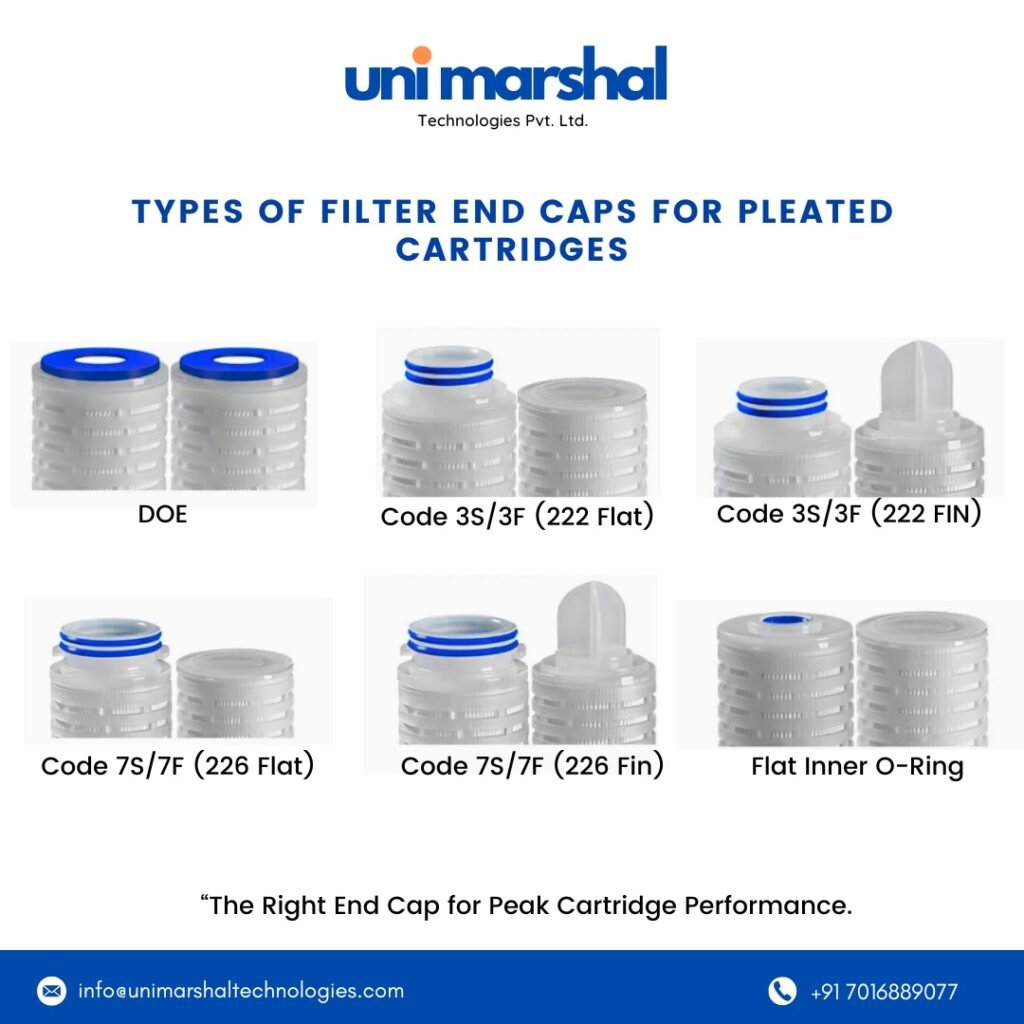

✅ Types of End Caps in Pleated Filter Cartridges

Understanding the various end connections can help you choose the right configuration for your filtration system:

🔹 1. DOE (Double Open End)

Description: Both ends are open and flat, allowing fluid to flow through the entire filter.

- Used in: Standard housings with knife-edge seals or spring-loaded caps

- Common Sizes: 10″, 20″, 30″, 40″

- Advantages: Simple design, economical, easy to install

🔹 2. SOE (Single Open End)

Description: One end is open for flow, and the other is closed with a specific end fitting for sealing.

There are several SOE variations based on end cap design:

a. 222 O-Ring with Flat Cap

- Sealing Method: O-ring seal + flat base

- Used in: Sanitary and pharmaceutical applications

- Benefit: Excellent sealing under pressure

b. 222 O-Ring with Fin

- Sealing Method: O-ring seal + guide fin

- Used in: Horizontal or vertical housings

- Benefit: Easy alignment and secure fit

c. 226 O-Ring with Flat Cap

- Sealing Method: Twin O-rings with flat cap

- Used in: Critical applications requiring leak-proof sealing

- Benefit: High-pressure sealing performance

d. 226 O-Ring with Fin

- Sealing Method: Twin O-rings + alignment fin

- Used in: High-purity systems and CIP/SIP housings

- Benefit: Reliable under thermal and mechanical stress

e. Threaded End Cap

- Sealing Method: Screw-type threading

- Used in: Customized or proprietary housings

- Benefit: Firm connection without bypass

🔹 3. Customized or Special End Caps

Some industries or OEMs require custom-designed end caps that integrate directly into specialized housings or machinery.

- Materials: PP, SS, PTFE, or custom polymer blends

- Custom options: Bayonet locks, spring guides, integrated handles

- Industries served: Aerospace, biotech, defense, automotive fluids

🏭 Applications by End Cap Type

| End Cap Type | Common Applications |

|---|---|

| DOE | Water treatment, general pre-filtration |

| 222 Flat | Pharma, beverages, cleanrooms |

| 222 Fin | Biotech, critical liquid handling |

| 226 Flat/Fin | CIP/SIP processes, sterile filtration |

| Threaded/Custom | OEM systems, closed-loop processes |

🔧 Why End Cap Compatibility Matters

- Improper end caps can cause leaks or filter failure

- Mismatched filters may not fit securely in housings

- The right end cap ensures maximum filtration efficiency and safety

Always verify end cap type compatibility with your filter housing design before ordering or installing.

🔹 Unimarshal – Manufacturer & Exporter of Custom Filter Cartridges

Unimarshal Technologies Pvt. Ltd. offers:

- Full range of pleated cartridge filters with DOE, 222, 226, threaded, and custom ends

- Material options for caps including PP, SS, PTFE

- Custom manufacturing for OEM and export markets

- Global deliveries to USA, Europe , UAE, Australia, New Zealand, Singapore, South Africa, and more

Whether you need standard cartridges or customized end configurations, we ensure precision, quality, and on-time delivery.

✅ Conclusion

Choosing the right end cap for pleated filter cartridges is vital to ensuring system compatibility, performance, and safety. At Unimarshal, we provide high-quality filters with a wide variety of end configurations to meet global industrial needs.

Contact us today to get expert guidance on selecting the ideal pleated filter cartridge for your application.