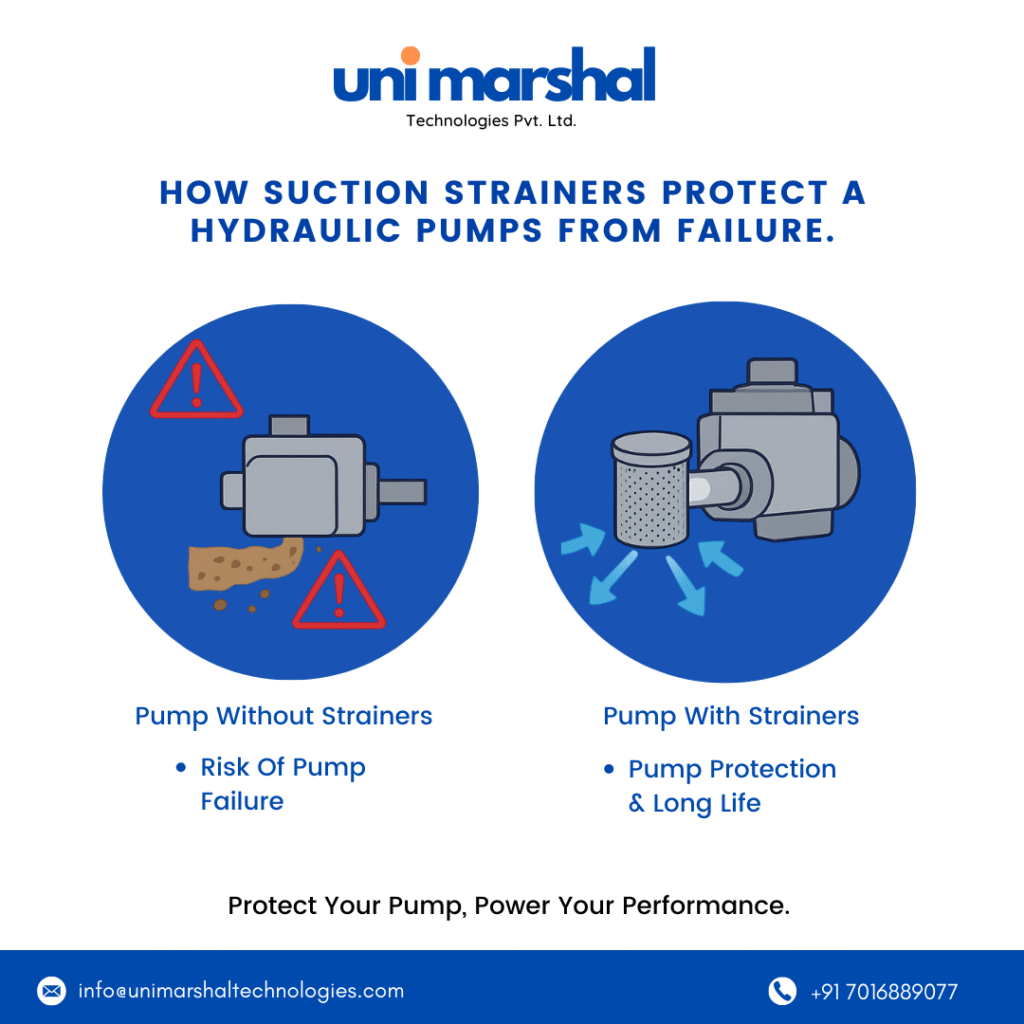

Hydraulic pumps are the heart of any power pack unit, driving fluid under pressure to keep machines running smoothly. However, even the most advanced pump can fail prematurely if contaminants like dirt, metal shavings, or fibers enter the system. This is where suction strainers play a critical role.

Table of Contents

ToggleTable of Contents

What is a Suction Strainer?

A suction strainer is a mesh filter element installed at the pump’s inlet, designed to trap large particles before they enter the hydraulic system. Unlike fine filters placed downstream, suction strainers act as the first line of defense, ensuring the pump receives only clean fluid.

How Suction Strainers Prevent Pump Failure

- Blocking Solid Contaminants

Suction strainers capture harmful debris such as welding slag, casting sand, and wear particles that can damage pump gears or vanes. - Protecting Pump Components

By stopping contaminants early, suction strainers reduce abrasion, scoring, and surface damage inside the pump, extending its operational life. - Maintaining Fluid Flow

A properly sized suction strainer ensures smooth, unrestricted flow into the pump, preventing cavitation and overheating – two leading causes of hydraulic pump failure. - Reducing Downtime and Costs

Pump failures often mean expensive repairs and machine stoppages. A reliable suction strainer minimizes these risks, keeping operations efficient and cost-effective. - Supporting Overall System Health

By keeping the pump safe, suction strainers also improve the lifespan of other hydraulic components like valves, actuators, and fine filters.

Applications in Hydraulic Power Pack Units

In India and worldwide, suction strainers are widely used in construction equipment, presses, injection molding machines, and heavy machinery where hydraulic power packs are essential.

Conclusion

Suction strainers may be small components, but their role in protecting hydraulic pumps is massive. By stopping contaminants at the source, they ensure longer pump life, reduced breakdowns, and reliable system performance.

At Unimarshal Technologies, we design and manufacture high-quality suction strainers tailored for hydraulic power pack units, helping industries achieve efficiency and reliability.