Table of Contents

ToggleTable of Contents

Introduction

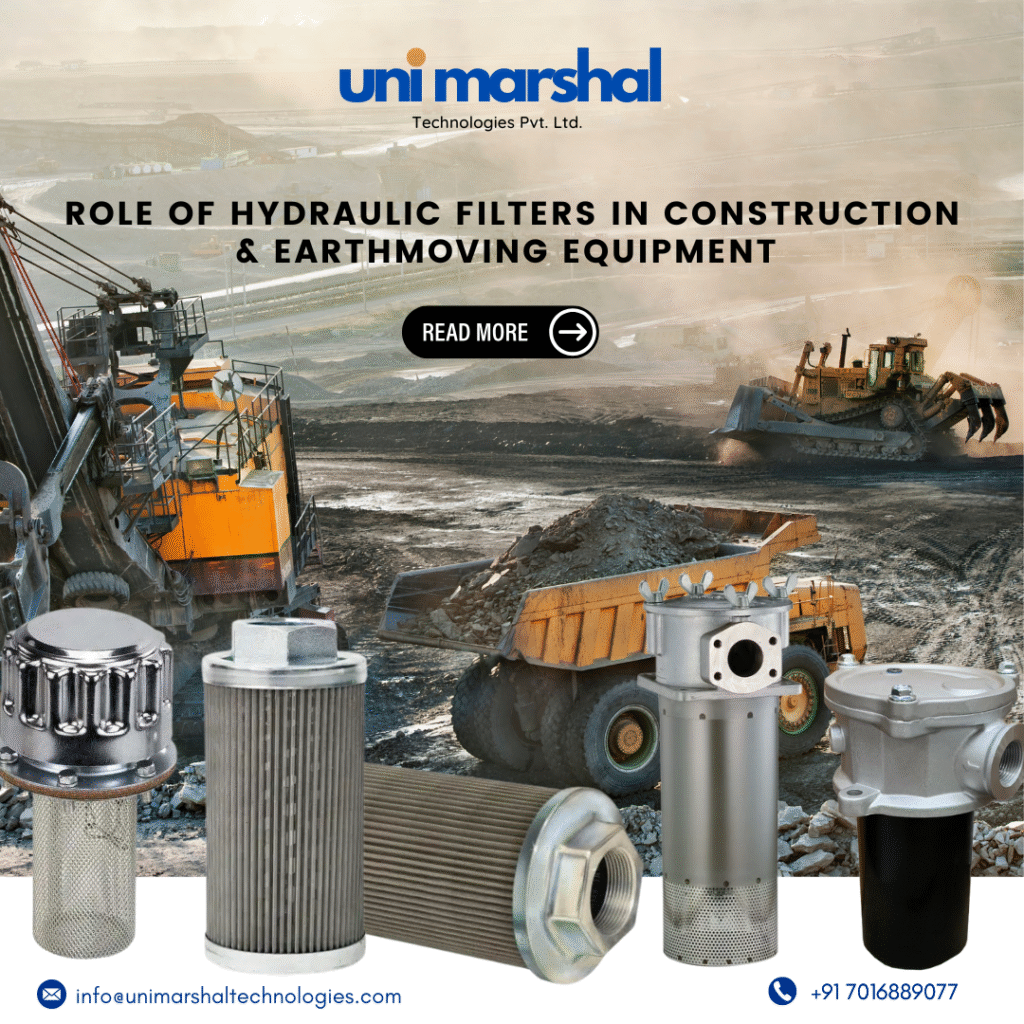

Hydraulic systems are the backbone of modern construction and earthmoving equipment. From excavators and loaders to bulldozers and cranes, these machines rely on hydraulic power to perform heavy-duty operations efficiently. One critical but often overlooked component that ensures the smooth functioning of these hydraulic systems is the suction strainer.

In this article, we’ll explore the importance of suction strainers in construction and earthmoving equipment, their role in protecting hydraulic pumps, and how choosing the right strainer improves performance and reduces downtime.

What is a Suction Strainer?

A suction strainer is a coarse filtration device installed at the inlet side of a hydraulic pump, usually inside the reservoir. Its primary function is to prevent large contaminants—such as dirt, welding slag, metal particles, or debris—from entering the pump and damaging critical hydraulic components.

Unlike fine filters, suction strainers typically use a wire mesh or perforated screen with a micron rating between 40 to 250 microns, allowing fluid to pass freely while blocking larger particles.

Why Suction Strainers are Essential in Construction & Earthmoving Equipment

1. Protection Against Harsh Environments

Construction and mining sites expose hydraulic systems to dust, mud, sand, and water contamination. Without a suction strainer, these contaminants can enter the pump inlet, causing rapid wear, cavitation, or even pump failure.

2. Extending Hydraulic Pump Life

Hydraulic pumps are one of the costliest components in heavy machinery. Suction strainers act as the first line of defense, ensuring only relatively clean oil reaches the pump, thereby extending its operational life.

3. Reducing System Downtime

Unplanned equipment failure can lead to costly downtime on construction projects. By trapping large debris early, suction strainers help prevent major breakdowns, keeping machines running longer and more reliably.

4. Improving Efficiency and Safety

A clogged or damaged pump can lead to pressure loss, overheating, or erratic machine behavior. Suction strainers maintain smooth hydraulic flow, ensuring safety and consistent performance in earthmoving tasks.

Applications of Suction Strainers in Heavy Machinery

- Excavators & Backhoes: Protect hydraulic pumps that power arms, booms, and buckets.

- Bulldozers: Ensure stable hydraulic flow for blade movement.

- Wheel Loaders: Prevent contamination during lifting and dumping operations.

- Cranes: Safeguard precise hydraulic control for lifting heavy loads.

- Mining Equipment: Withstand dusty and abrasive environments by filtering large contaminants.

Selecting the Right Suction Strainer for Construction Equipment

When choosing a suction strainer, consider the following factors:

- Micron Rating: Typically 74–125 microns for heavy-duty machines.

- Flow Rate Capacity: Must match the pump flow requirements to prevent cavitation.

- Material of Construction: Stainless steel or brass mesh offers durability in harsh environments.

- Mounting Style: Tank-top strainers, threaded strainers, or flanged types depending on the reservoir design.

- Serviceability: Easy-to-clean and replaceable elements reduce maintenance costs.

Maintenance Best Practices

- Regular Inspection: Check suction strainers for clogging, cracks, or damage.

- Cleaning Intervals: Clean strainers during scheduled maintenance or oil replacement cycles.

- Avoid Oversizing Micron Ratings: Too coarse a mesh may let contaminants pass through.

- Monitor Pump Health: Excessive noise or cavitation may indicate strainer blockage.

Conclusion

In construction and earthmoving equipment, suction strainers play a vital role in protecting hydraulic systems from contamination and premature failure. By preventing large particles from entering the hydraulic pump, they help reduce downtime, extend component life, and improve overall machine performance.

Choosing the right suction strainer and following proper maintenance practices ensures that your heavy-duty equipment delivers maximum efficiency, reliability, and safety on demanding job sites.

Suction Strainers – Global Supply by Unimarshal Technologies

At Unimarshal Technologies Pvt. Ltd., we manufacture and export high-quality hydraulic suction strainers for construction and earthmoving equipment across the world. Our strainers are engineered for durability, optimum flow capacity, and reliable pump protection.

India

As one of the leading suction strainer manufacturers in India, we supply to OEMs and contractors across major cities like Delhi, Mumbai, Pune, Chennai, Hyderabad, and Bangalore, supporting the fast-growing infrastructure sector.

United States & North America

We provide hydraulic suction strainers for construction equipment in the USA, Canada, and Mexico, serving industries such as mining, construction, and earthmoving contractors who demand reliable hydraulic filtration solutions.

Europe

Our suction strainers are trusted by companies in Germany, Italy, and the UK, where high standards of efficiency and equipment longevity are critical in construction machinery.

Middle East & UAE

In Dubai, Abu Dhabi, and across the UAE, our suction strainers are widely used in construction and oilfield machinery, ensuring uninterrupted operation in challenging desert environments.

Australia & Asia-Pacific

With increasing demand in Australia, Singapore, and South-East Asia, we supply robust suction strainer solutions for earthmoving equipment operating in mining and construction projects.

Africa

As a growing supplier to South Africa and other African markets, we provide cost-effective yet durable suction strainers that help improve hydraulic equipment life in mining and infrastructure development projects.