If you’re running an industrial operation, energy costs are probably a big part of your monthly headaches. And if filtration is anywhere in your process—whether it’s air, liquid, or gas—you might be spending more on energy than you need to. One of the often-overlooked culprits? Pressure drop.

It sounds like an engineering term (and it is), but once you understand how pressure drop works—and how to read a pressure drop curve—you’ll see how a small change in filter selection can lead to big savings over time.

Table of Contents

ToggleSo, What Exactly Is Pressure Drop?

In simple terms, pressure drop is the loss of pressure as a fluid passes through a filter. Every filter creates some resistance—that’s normal. But the more resistance there is, the harder your pump, blower, or fan has to work to keep things moving. And that means more energy consumption.

What’s a Pressure Drop Curve?

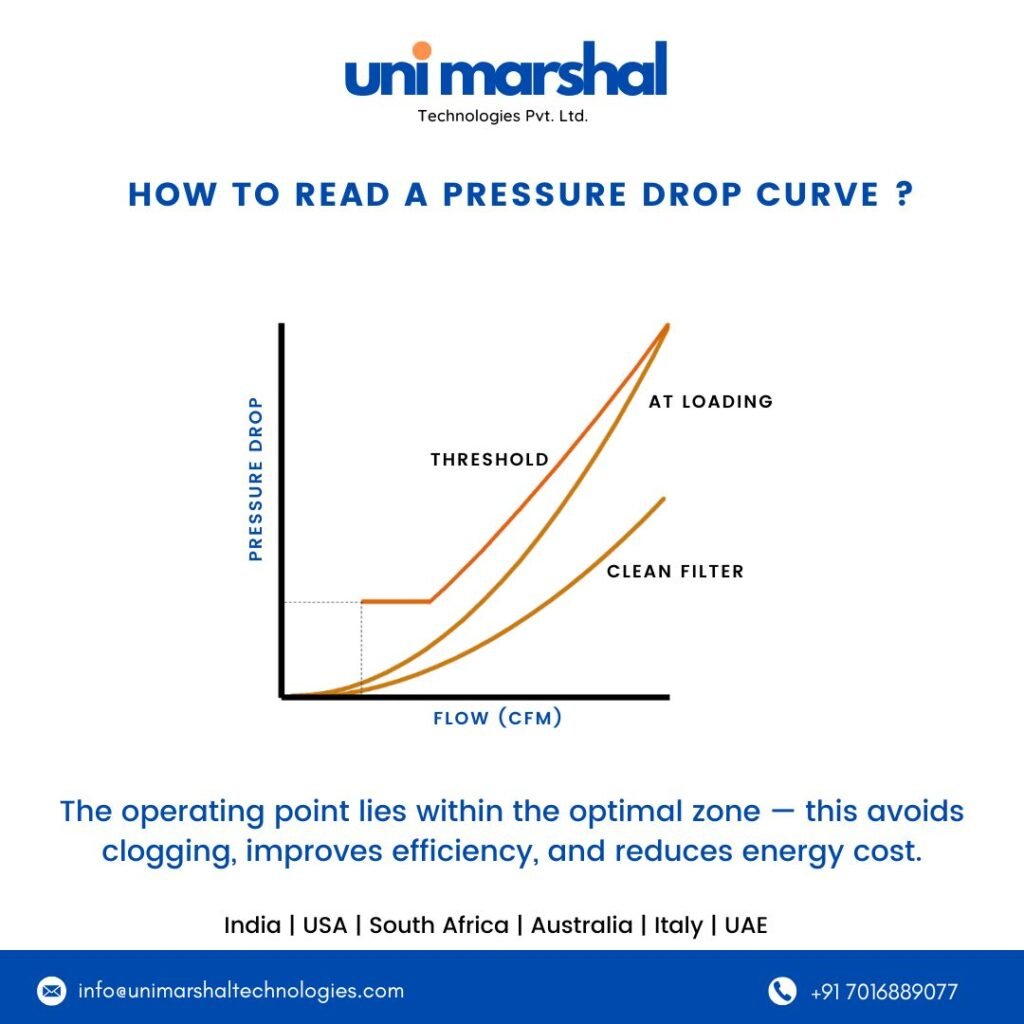

Imagine you’re looking at a graph. One axis shows flow rate, and the other shows how much pressure is being lost at each of those flow rates. That’s a pressure drop curve.

Manufacturers provide these curves to show how a specific filter will perform under different conditions. They help you understand whether the filter you’re considering is going to operate efficiently—or become an energy hog.

Why Should You Care?

Here’s where things get practical. Let’s say you’re filtering water at 1000 LPM. You have two filter options:

- Filter A has a pressure drop of 0.8 bar

- Filter B has a pressure drop of 0.4 bar

That 0.4 bar difference might not sound like much—but over time, and over thousands of liters per day, it adds up. You’re asking your pump to do more work, and it’s going to show up in your energy bill. In many cases, the extra energy cost can far outweigh the difference in price between the two filters.

The Real Cost of Choosing the Wrong Filter

Using a filter without checking the pressure drop curve is like buying a car without checking the mileage. You might save a few bucks upfront, but you’ll pay more in the long run. A high pressure drop means:

- Higher energy consumption

- Faster wear and tear on pumps or blowers

- Increased maintenance needs

- More frequent filter replacements

How to Use Pressure Drop Curves the Smart Way

- Look at your flow rate first: Know your system’s requirements before you shop.

- Compare curves, not just prices: A cheaper filter with a high pressure drop might cost more in the long run.

- Think long term: Factor in energy costs, not just the upfront price.

- Talk to your supplier: A good supplier should help you interpret these curves and choose the best option.

Final Thought

Filters don’t just trap particles—they affect your entire system’s efficiency. And when you understand how pressure drop curves work, you’re in a much better position to make smart decisions that save energy, reduce downtime, and lower operating costs.

At Unimarshal Technologies, we don’t just sell filters—we help you choose the right ones. Ones that strike the right balance between performance and efficiency.

Because in industrial filtration, what you don’t know about pressure drop can cost you.