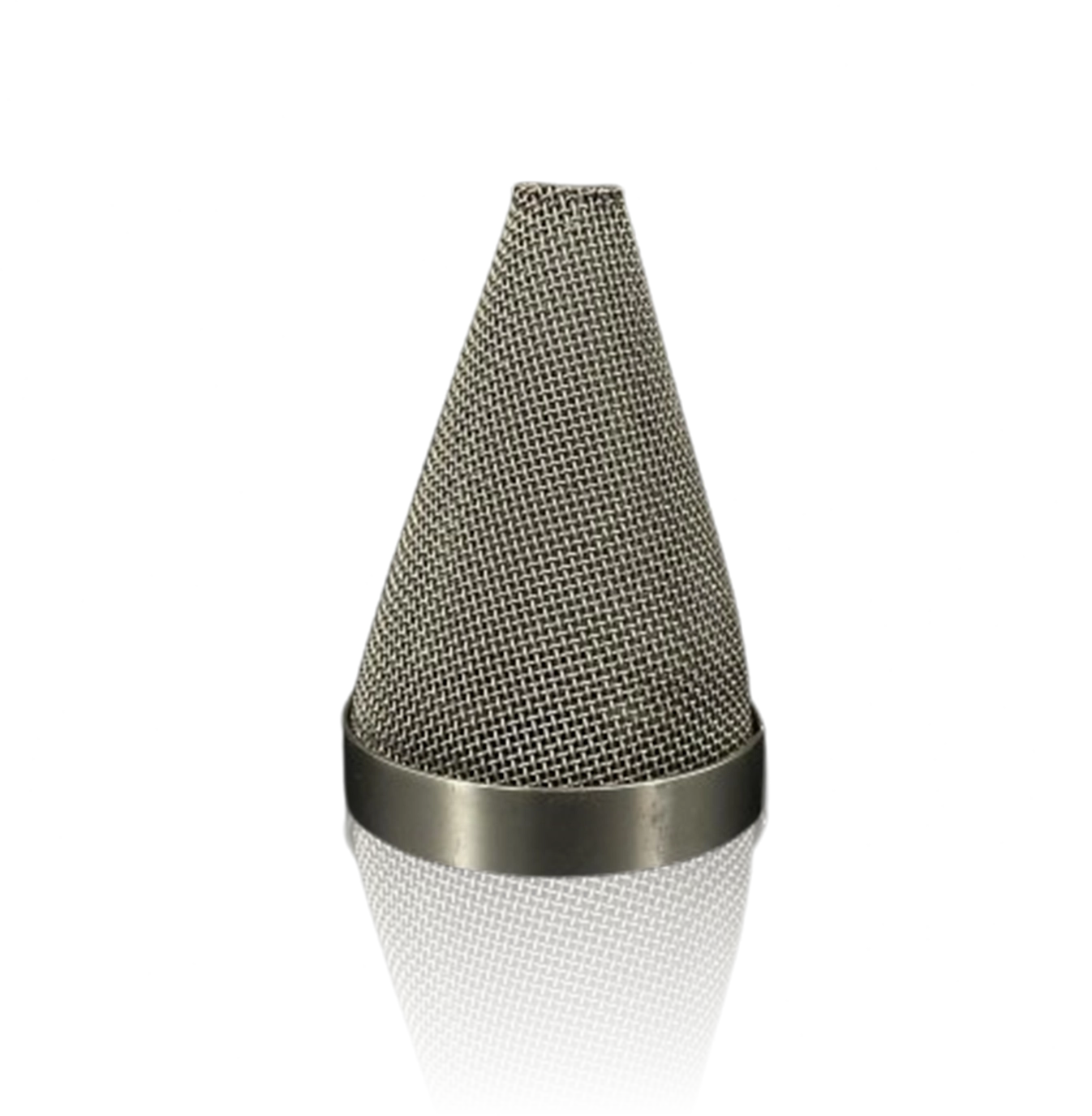

Conical Strainer

- Unimarshal Technologies

- Conical Strainer

Conical Strainer

Conical Strainer Manufacturer

Unimarshal Technologies Pvt. Ltd. is a reliable manufacturer of conical strainers built for efficient filtration in liquid, gas, and air systems. Our designs focus on consistent performance and long service life across demanding applications.

With proven expertise as a Conical Strainer supplier and Conical Strainer exporter, we deliver custom-engineered solutions that ensure effective contaminant removal, low pressure drop, and dependable results for chemical, food, oil and industrial sectors.

Description

- Robust Construction: Made from high-grade stainless steel (SS 304/316/316L) for superior strength, corrosion resistance, and long service life in demanding industrial environments.

- Wide Micron Range: Available in micron ratings from 5 to 500 µm, ensuring precise particle retention for various industrial and process applications.

- Customizable Design: Offered in multiple diameters, lengths, and end connections to suit specific system requirements and operational performance needs.

- High Flow Capacity: Engineered for minimal pressure drop and optimized flow efficiency even in high-viscosity or high-pressure systems, ensuring consistent and reliable performance.

- Easy Installation & Maintenance: Lightweight, compact design with easy access for cleaning and replacement, without special tools or downtime issues.

- Temperature & Pressure Resistant: Suitable for demanding industrial conditions with high temperature and pressure tolerance under continuous and heavy-duty operating environments.

- Global Compliance: Manufactured to meet international filtration and safety standards for export across global markets with strict quality control and certification processes.

Features

- Mainly useful for coarser filtration, however can be provided for fine filtration also.

- Higher gauge perforation support can be selected with respect to operating pressure of filter housing and differential pressure requirements.

- Bidirectional (Outside to Inside and Inside to Outside) low direction can be processed upon request / requirements.

M.O.C

- SS 304

- SS 316

- SS 316 L

- Alloy Steel

Advantages

- Large Filtration Surface Area:

- Improved Filtration Efficiency

- Space-Efficient Design

- Easy Installation and Replacement

- Versatility

Applications

- Water and Waste Water

- Chemicals

- Oil & Gas

- Pharma

- Textiles

- Process Industry

- Petrochemicals etc.

Frequently Ask Questions

A conical strainer is designed to remove impurities from liquids or gases efficiently. Its unique shape allows for better flow and filtration, ensuring cleaner output with minimal pressure drop.

It is widely used in industries like chemical processing, food and beverage, pharmaceuticals, and water treatment where effective filtration is critical.

Filters are typically made from stainless steel, mesh, or specialized alloys to ensure durability, corrosion resistance, and long-term performance.

Replacement or cleaning depends on usage and the type of fluid being filtered. Regular inspection is recommended to maintain efficiency and prevent clogging.

Yes, conical filters are designed to withstand varying pressure levels. However, selecting the right specification is essential for optimal performance.

Its conical shape provides a larger surface area than flat filters, allowing higher flow rates and longer service life. It’s more efficient in trapping fine particles.

Yes, these filters are user-friendly and can be installed with standard fittings. Routine cleaning is straightforward, reducing downtime.

Yes, filters come in various sizes and micron ratings to suit different applications and filtration requirements.

Consider factors like flow rate, fluid type, operating pressure, and particle size to select a filter that meets your needs effectively.

It ensures high filtration efficiency, reduces maintenance costs, improves system longevity, and maintains product quality consistently.