Table of Contents

ToggleIntroduction

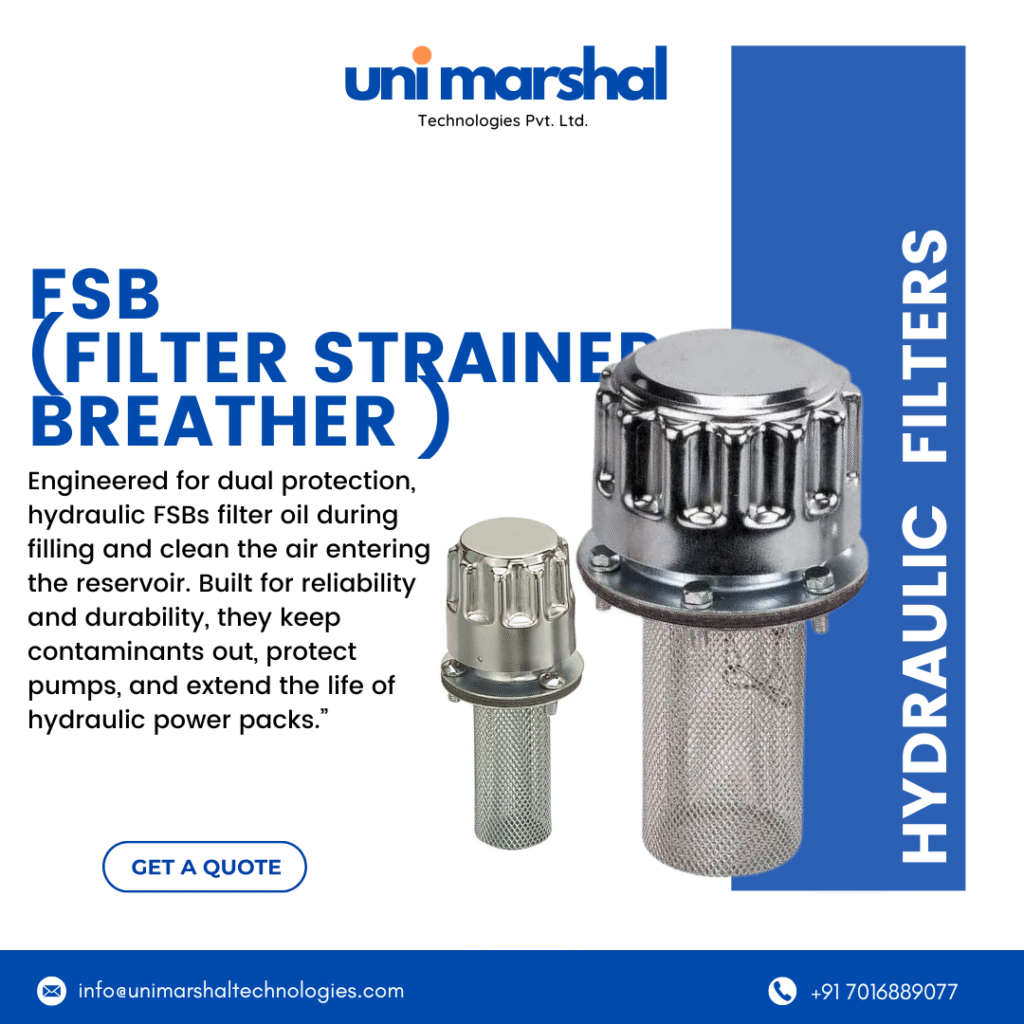

Hydraulic systems depend on clean, contaminant-free oil to keep pumps, valves, and actuators working efficiently. One of the most overlooked, yet critical, components in a hydraulic power pack is the FSB (Filter Strainer Breather). By combining the functions of a tank breather and suction strainer, the FSB provides dual protection for hydraulic reservoirs, ensuring longer system life and lower maintenance.

What is an FSB (Filter Strainer Breather)?

An FSB is a multi-functional unit mounted on the hydraulic reservoir. It performs two essential tasks:

- Breather Function: Allows air exchange in and out of the tank as oil level rises or falls, while preventing dust, moisture, and airborne particles from entering.

- Strainer Function: Filters the hydraulic oil during filling or suction, stopping larger contaminants from entering the reservoir.

This dual-purpose design makes the FSB an economical and effective solution for hydraulic power packs.

Why FSB is Critical in Hydraulic Power Packs

- Contamination Control

Around 70–80% of hydraulic failures are caused by contamination. The FSB ensures cleaner oil entry and cleaner air flow, protecting pumps and valves. - Pump Protection

By straining oil before it enters the suction line, the FSB prevents fibers, welding slag, or large particles from reaching the pump. - Pressure Equalization

The breather prevents vacuum formation in the reservoir as oil is pumped out, ensuring smooth flow without cavitation. - Cost-Effective Maintenance

A properly selected FSB reduces wear, lowers filter replacement frequency, and minimizes downtime.

Design Features of Hydraulic FSB

- Micron Rating: Typically 125–250 µm, suitable for blocking coarse contaminants.

- Breather Element: Paper, felt, or synthetic media to trap airborne dust.

- Mounting Type: Tank-top mounting with filler cap for easy oil filling.

- Material: Stainless steel mesh or plated steel for durability.

- Options: Lockable filler caps, dipsticks for oil level checking, and magnetic strainers for capturing metallic debris.

Applications of FSB in Industry

FSBs are widely used in:

- Hydraulic power packs for press machines

- Plastic injection molding machines

- Material handling equipment

- Construction and mining hydraulics

- Industrial automation systems

Anywhere a hydraulic reservoir is used, an FSB provides essential first-line defense.

Practical Tips for Users

- Always match the FSB micron rating to the pump manufacturer’s recommendation.

- Clean the strainer element at regular maintenance intervals.

- Replace the breather element if clogged or saturated.

- Use stainless steel mesh for durability in harsh environments.

Conclusion

The Hydraulic FSB (Filter Strainer Breather) is more than just a filler cap — it’s a critical component that ensures clean air, clean oil, and reliable pump performance. By combining breather and strainer functions, FSBs protect hydraulic power packs from contamination-related failures, extend equipment life, and reduce overall maintenance costs.

At Unimarshal Technologies, we supply high-quality FSBs engineered for diverse industrial applications in India, UK, Africa, Japan, Russia, and Australia.

Q1. What is a hydraulic FSB (Filter Strainer Breather)?

A hydraulic FSB is a tank-mounted component that combines a suction strainer and breather filter to protect hydraulic reservoirs from contaminants.

Q2. Why is an FSB important in hydraulic power packs?

An FSB ensures clean oil filling, filters suction oil, and allows dust-free air exchange, preventing pump damage and extending system life.

Q3. What micron rating is used in hydraulic FSB strainers?

Hydraulic FSB strainers typically 40 microns, providing coarse filtration to block large particles without restricting oil flow.

Q4. How often should a hydraulic FSB be maintained?

The strainer should be cleaned and the breather element checked during every oil change or scheduled maintenance cycle to prevent clogging.

Q5. Where are hydraulic FSBs commonly used?

FSBs are widely used in hydraulic power packs for presses, injection molding, material handling, construction, and industrial automation systems.