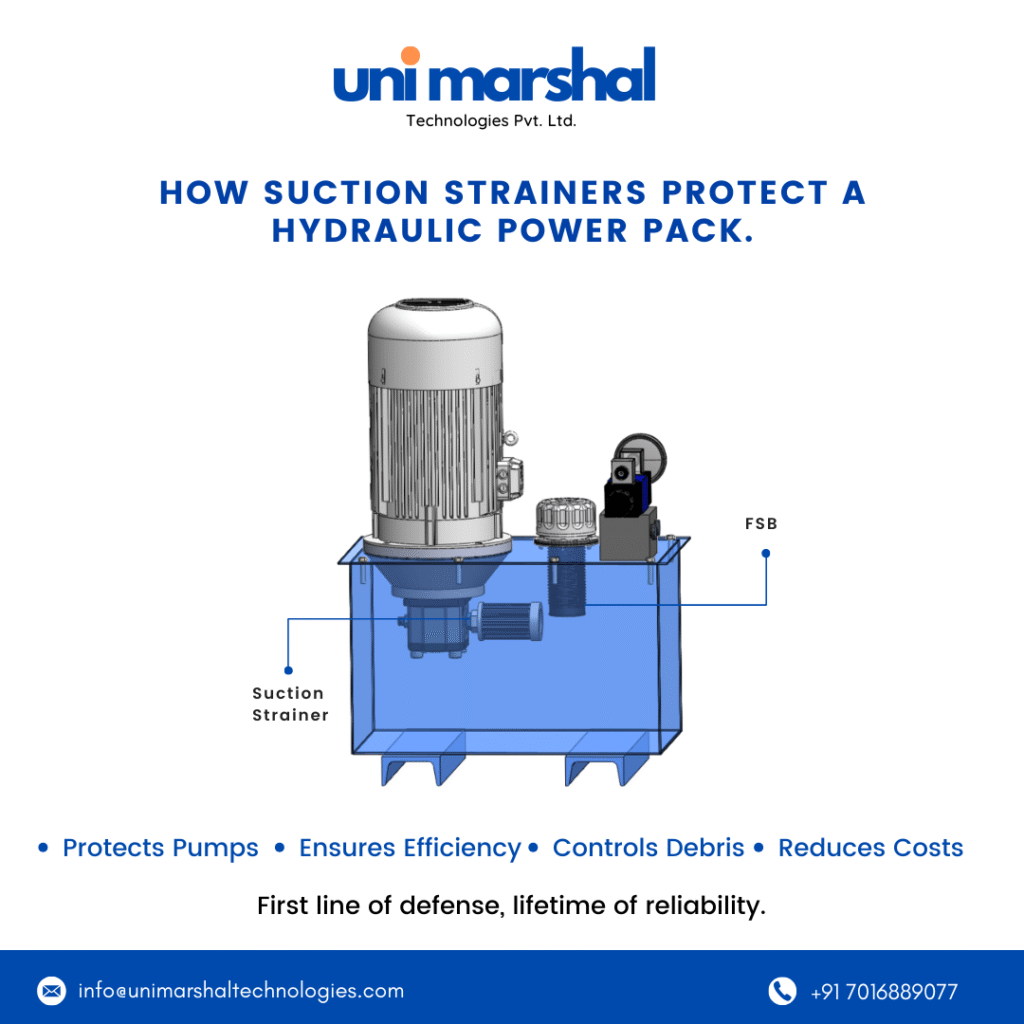

Suction Strainer – A hydraulic power pack is the heart of many industrial machines, supplying pressurized fluid to drive cylinders, motors, and actuators. However, the efficiency of a power pack depends heavily on the cleanliness of its hydraulic fluid. One of the simplest yet most important components ensuring this cleanliness is the suction strainer.

At Unimarshal Technologies, we manufacture suction strainers designed specifically for hydraulic power packs, delivering durability, protection, and efficiency.

Table of Contents

ToggleWhat is a Suction Strainer in a Hydraulic Power Pack?

A suction strainer is installed on the suction line of the hydraulic power pack pump. Its role is to:

- Prevent large contaminants like metal chips, dust, or debris from entering the pump.

- Protect the pump from cavitation and premature wear.

- Reduce load on downstream filters.

By capturing coarse particles at the entry point, suction strainers keep the entire hydraulic power pack running smoothly.

Why Are Suction Strainers Critical in Hydraulic Power Packs?

- Pump Protection – Prevents scoring, wear, and pump failure.

- Consistent Performance – Ensures uninterrupted hydraulic fluid flow.

- Lower Maintenance Costs – Extends the life of fine filters and pumps.

- System Reliability – Minimizes downtime in critical applications.

Applications of Suction Strainers in Hydraulic Power Packs

- Industrial Machinery – Press machines, injection molding, material handling systems.

- Construction Equipment – Hydraulic cranes, loaders, excavators powered by hydraulic packs.

- Automotive Industry – Test rigs, robotic arms, and precision hydraulic equipment.

- Mining & Drilling – Power packs used in rugged and dusty environments.

- Agriculture – Tractors, harvesters, and irrigation systems powered by hydraulic packs.

Technical Considerations for Choosing the Right Suction Strainer

When selecting a suction strainer for a hydraulic power pack, factors to consider include:

- Micron Rating: Typically 75–200 microns to avoid pump starvation.

- Flow Rate: Strainer area should be 3–4 times the pipe cross-section to prevent pressure drop.

- Material of Construction: Stainless Steel 304/316 for corrosion resistance, Duplex Steel for heavy-duty conditions.

- Mounting Style: Tank top strainers or inline suction strainers depending on the system design.

- Cleanability: Reusable mesh strainers allow easy maintenance.

Maintenance Best Practices

- Inspect suction strainers during regular hydraulic power pack servicing.

- Clean strainers to prevent clogging and pump cavitation.

- Replace damaged or worn-out strainers immediately.

- Always follow OEM recommendations for inspection intervals.

Why Choose Unimarshal Technologies?

- Specialized in suction strainers for hydraulic power pack units.

- Manufacturing expertise in SS 304, SS 316, Duplex Steel, and Mild Steel strainers.

- Export-ready solutions trusted across India, Africa, UK, Japan, Russia, and Australia.

- Proven track record of supplying to industries where hydraulic reliability is mission-critical.

Conclusion

Hydraulic power packs depend on clean fluid for long-lasting performance, and suction strainers are the first step in achieving that. By preventing contaminants at the entry point, suction strainers protect pumps, reduce failures, and enhance overall system efficiency.

At Unimarshal Technologies, we deliver robust and high-performance suction strainers designed specifically for hydraulic power pack units. Partner with us for reliable, efficient, and globally trusted filtration solutions.

What is the purpose of a suction strainer in a hydraulic power pack?

A suction strainer prevents dirt, debris, and large contaminants from entering the pump, protecting it from damage and ensuring smooth hydraulic system performance

What micron rating is suitable for a hydraulic suction strainer?

Hydraulic suction strainers are generally designed with coarse ratings of 75–200 microns, preventing pump starvation while effectively blocking large particle

Can suction strainers be cleaned and reused?

Yes. Most suction strainers are washable and reusable, especially when made from stainless steel mesh. Regular cleaning ensures longer service life and efficiency.

Where can I buy suction strainers for hydraulic power packs in India?

You can source suction strainers directly from Unimarshal Technologies, a trusted Indian manufacturer and exporter supplying across major industrial hubs.