In the world of industrial filtration, maintaining purity, protecting equipment, and improving process efficiency are critical to operational success. One essential method that ensures this level of protection is depth filtration. From chemicals to food and beverage production, depth filtration plays a pivotal role in removing contaminants and extending the life of downstream equipment.

At Unimarshal Technologies Pvt. Ltd., a trusted industrial filter manufacturer and exporter in India, we specialize in high-performance filtration solutions including depth filter cartridges for a wide range of applications.

Table of Contents

ToggleTable of Contents

What is Depth Filtration?

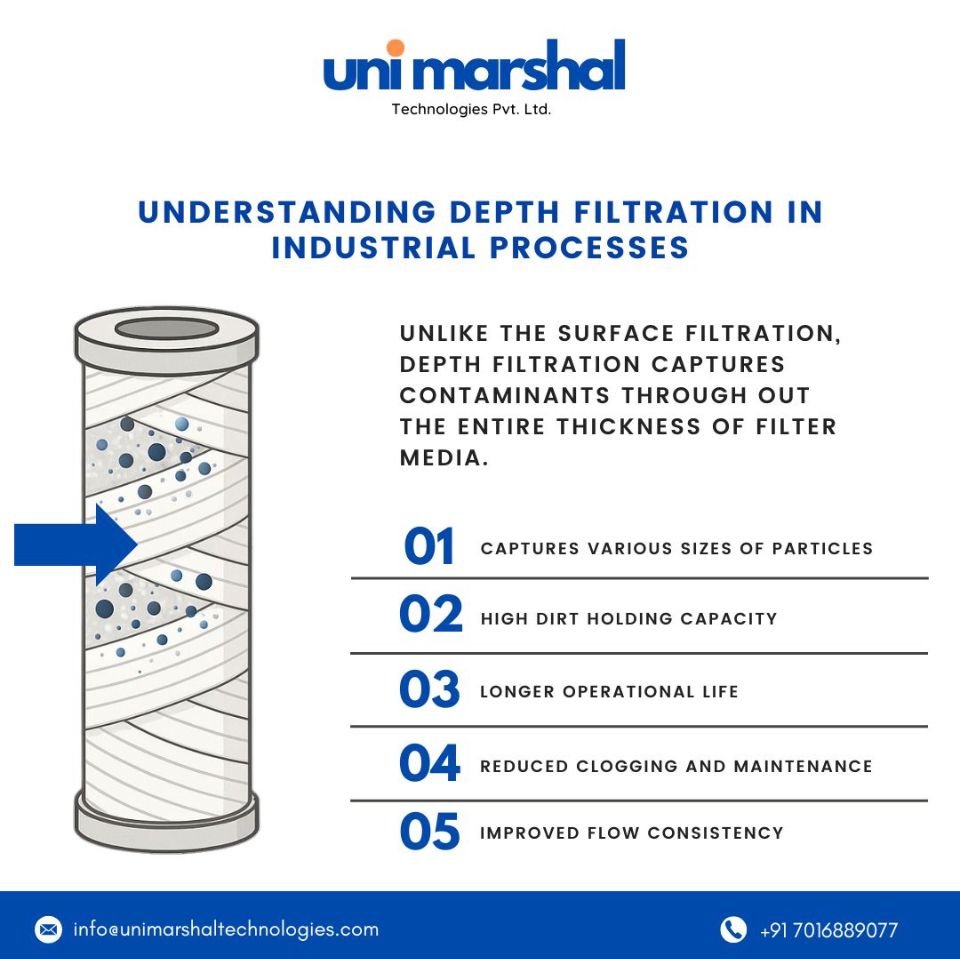

Depth filtration is a process where particles are captured throughout the thickness of the filter media, rather than just on the surface. The filter is typically made from fibrous materials such as polypropylene, cellulose, or glass fiber, formed into a matrix that creates a tortuous path for particles to pass through.

This multi-layer structure traps contaminants of various sizes at different depths, making it highly effective for removing suspended solids, gel-like particles, and viscous contaminants.

How Depth Filters Work

In depth filtration, liquid flows through a porous medium where larger particles are retained on the outer layers while smaller ones get trapped deeper inside the media. This progressive capture mechanism offers:

- High dirt-holding capacity

- Longer service life

- Stable flow rates under varying load

The most common configurations are melt-blown filter cartridges, wound filter cartridges, and resin-bonded filters, each designed for specific industrial applications.

Applications of Depth Filtration in Industrial Processes

Depth filters are widely used across multiple industries due to their reliability and compatibility with different process fluids:

- Pharmaceutical & Biotech: Particle reduction before sterilization

- Food & Beverage: Clarification of liquids like wine, beer, and syrups

- Water Treatment: Sediment removal in pre-filtration stages

- Chemical Processing: Filtering aggressive liquids and viscous fluids

- Paints & Inks: Removing gels and insoluble particles

- Oil & Gas: Protection of membranes and equipment in upstream/downstream systems

Benefits of Using Depth Filter Cartridges

- Superior Dirt-Holding Capacity: Due to their layered structure, depth filters last longer and handle higher contamination loads.

- Broad Chemical Compatibility: Suitable for acidic, alkaline, or solvent-based liquids.

- Low Cost of Operation: Reduced downtime and replacement frequency.

- Thermal and Mechanical Stability: Operates under high pressure and temperature conditions.

- Versatile Micron Ratings: Available from 1 to 100 microns.

Depth Filtration vs Surface Filtration

While surface filters trap particles on the outer surface (like pleated filters), depth filters retain particles within the media matrix. Depth filtration is ideal for high solid load applications where long service life and robustness are needed.

Unimarshal Technologies – Your Reliable Partner for Industrial Depth Filtration

As a leading manufacturer and exporter of depth filter cartridges in India, Unimarshal Technologies provides quality-driven solutions tailored to industrial demands. Our filters meet international standards and are exported to countries like the USA, UAE, UK, Germany, Australia, South Africa, and more.

Whether you’re dealing with high particulate loads or need a stable pre-filtration solution, our depth filters offer unmatched performance, consistency, and value.

Conclusion

Understanding depth filtration is essential for industries looking to enhance process reliability and product quality. With benefits like high dirt retention, extended filter life, and broad chemical resistance, depth filters are an indispensable part of modern industrial systems.

Need help choosing the right depth filter? Contact Unimarshal Technologies Pvt. Ltd. today for expert support and customized solutions.