Table of Contents

ToggleIntroduction

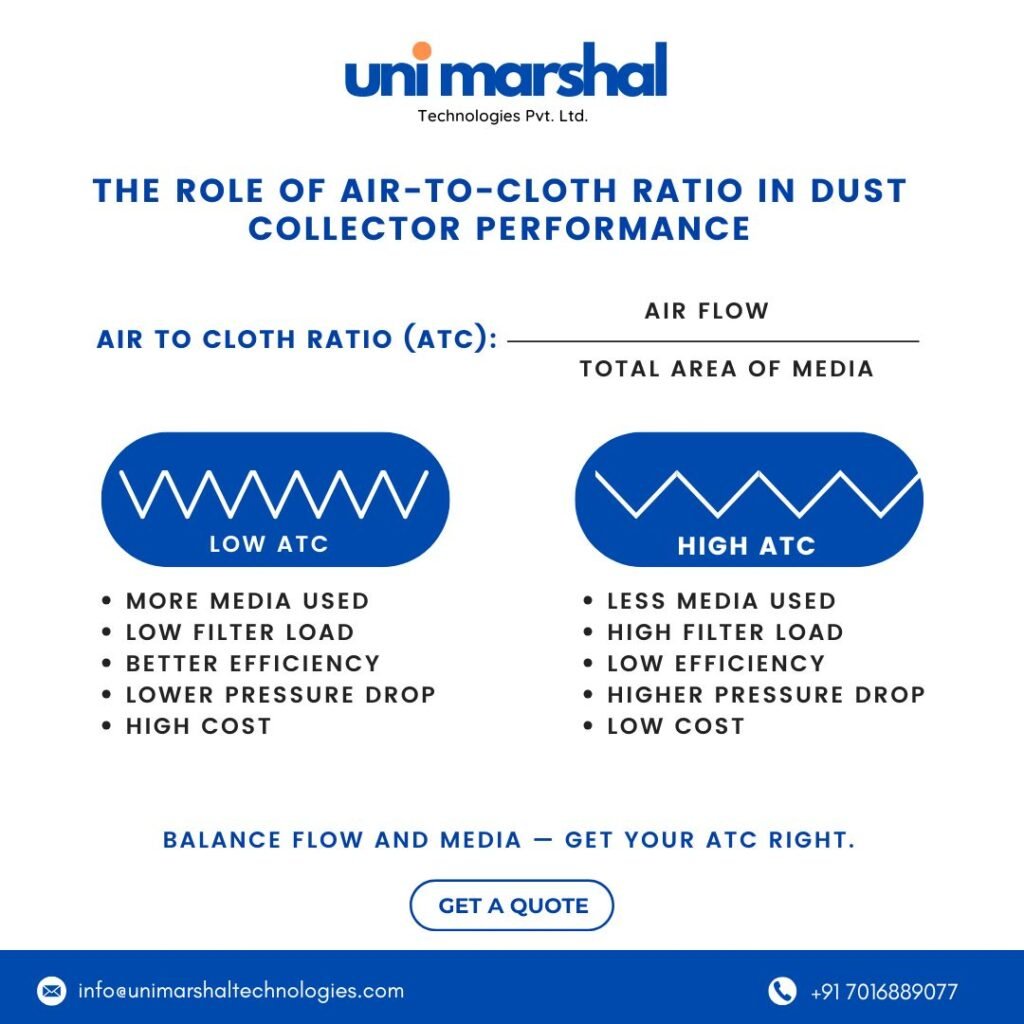

In industrial dust collection and air filtration systems, air-to-cloth ratio (ATC) plays a critical role in determining system efficiency, filter life, and energy consumption. Whether you’re managing filtration in cement, pharmaceuticals, HVAC, food processing, or manufacturing, choosing the right ATC can significantly affect your system’s performance.

At Unimarshal Technologies, we help you understand and implement the best filtration practices to ensure cleaner operations and longer filter life.

What Is Air-to-Cloth Ratio?

The air-to-cloth ratio is the volume of air (in cubic feet per minute or CFM) that passes through one square foot of filter media.

Formula:

ATC = Airflow (CFM) ÷ Filter Media Area (sq. ft.)

A lower ATC means more filter surface area for the same amount of airflow, while a higher ATC means less surface area, increasing the load on each square inch of media.

Why Air-to-Cloth Ratio Matters

1. Filtration Efficiency

A well-balanced ATC ensures that dust particles are effectively captured, minimizing bypass and ensuring cleaner air.

2. Filter Life

Lower ATC results in less stress on the media, reducing the frequency of replacements and maintenance.

3. Pressure Drop

Higher ATC ratios increase resistance in the system, leading to greater energy consumption and blower wear.

4. System Downtime

Overloaded filters clog faster. Optimized ATC helps maintain longer operating cycles with minimal downtime.

Recommended Air-to-Cloth Ratios by Application

| Industry/Application | Suggested ATC (CFM/sq.ft.) |

|---|---|

| Light Dust (Pharma, Food) | 3:1 – 4:1 |

| General Industrial Dust | 4:1 – 6:1 |

| Heavy Dust (Cement, Mining) | 2:1 – 3:1 |

| Fine Particulates (Powder Coating, Welding Fumes) | 1.5:1 – 2.5:1 |

Tip: Always consult with a filtration expert to tailor the ATC for your specific dust load and airflow.

Visualizing the Difference

Imagine two filters processing the same amount of air:

- Filter A has more pleats (higher cloth area) → Low ATC

- Filter B has fewer pleats (lower cloth area) → High ATC

Result:

Filter A runs longer, performs better, and reduces pressure drop. Filter B clogs faster, reducing system efficiency and increasing maintenance costs.

Unimarshal’s Approach to Optimized ATC

At Unimarshal Technologies Pvt. Ltd., we engineer and supply a wide range of filtration solutions including:

- Pleated Dust Collection Filters

- Bag Filter Housings

- Cartridge Filters & Housings

- HEPA & Pocket Filters

- Custom Air and Gas Filter Cartridges

Our design philosophy ensures optimal media selection, pleat design, and filter configuration for the best ATC performance in real-world industrial conditions.

Conclusion

Choosing the right air-to-cloth ratio is not just a technical decision—it’s a strategic one. A proper ATC helps your operation achieve:

Higher filtration efficiency

Lower energy costs

Extended filter lifespan

Minimal system downtime

Let Unimarshal help you engineer the perfect filtration solution. Get in touch with us today for custom filter designs and expert consultation.