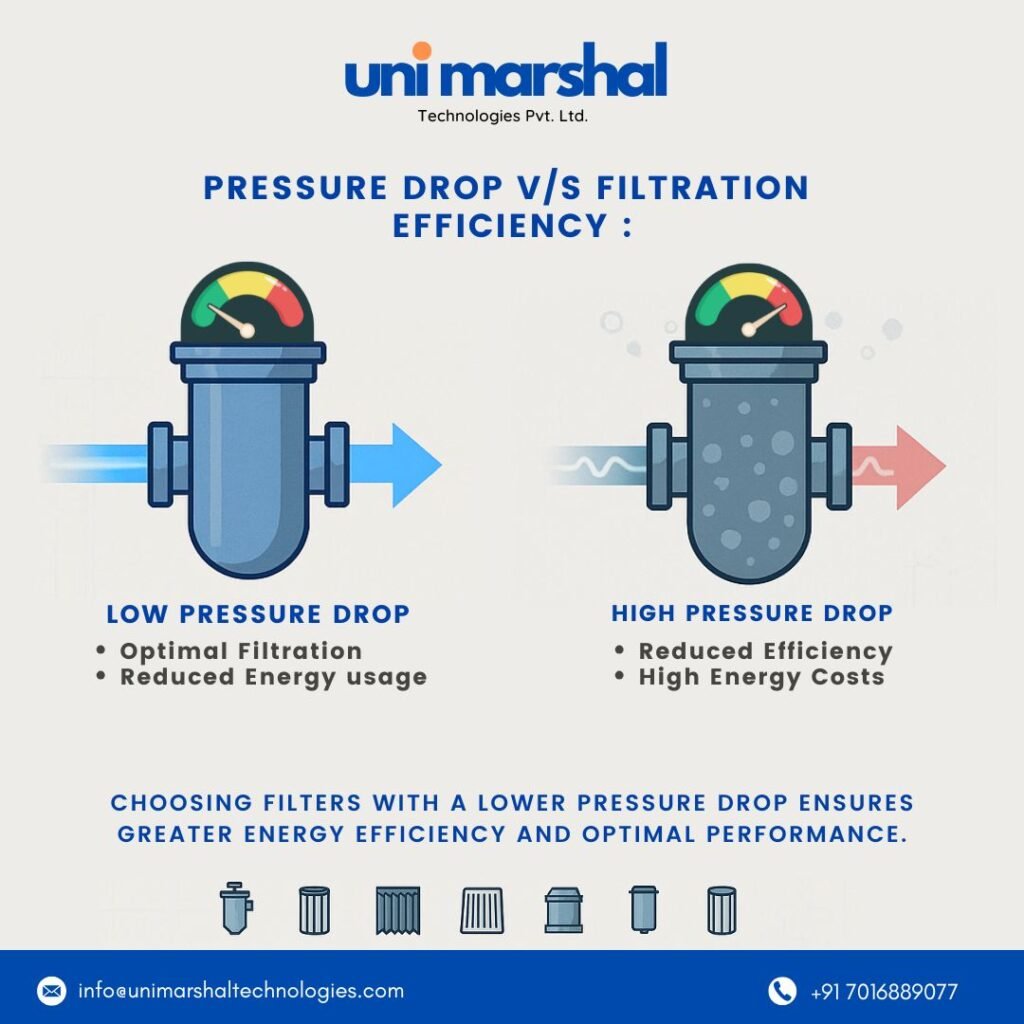

Pressure drop is a critical concept in any fluid or air filtration system. It refers to the reduction in pressure as a fluid or gas flows through a filter element. While some pressure drop is inevitable, excessive resistance can signal inefficiencies in the system.

Table of Contents

ToggleWhat Causes Pressure Drop?

When fluid or air moves through a filter, particles are captured by the filtration media. Over time, as the filter collects more contaminants, the resistance to flow increases. A properly sized and clean filter will maintain a low pressure drop, ensuring smooth flow and efficient operation. In contrast, a high pressure drop typically indicates:

- A clogged or saturated filter

- An undersized filter element

- Improper system design or flow rate

Why Pressure Drop Matters

Managing pressure drop is essential for maintaining system efficiency and minimizing operational costs. If left unchecked, high pressure drop can:

- Increase energy consumption due to greater effort required to maintain flow

- Lower process efficiency by restricting output or compromising performance

- Shorten filter life, leading to more frequent replacements and higher maintenance costs

How Unimarshal Technologies Helps

At Unimarshal Technologies, we specialize in designing and manufacturing filtration solutions that balance effective particulate capture with minimal pressure resistance. Our range of filter housings and cartridges — including pleated, spun, and cartridge filters — are optimized for both performance and durability.

Whether you’re filtering air, liquids, or gases, our systems are engineered to maintain flow integrity while reducing strain on your equipment.

Learn More

To explore our complete range of industrial filtration products and solutions, visit:

www.unimarshaltechnologies.com